Brand Introduction

Lumberg – We are Family-run

We are an independent, family-run company based in Germany – and have been for a good 87 years now. Our success is based on sustainable performance, technical solution competence – and our “passion for connections”.

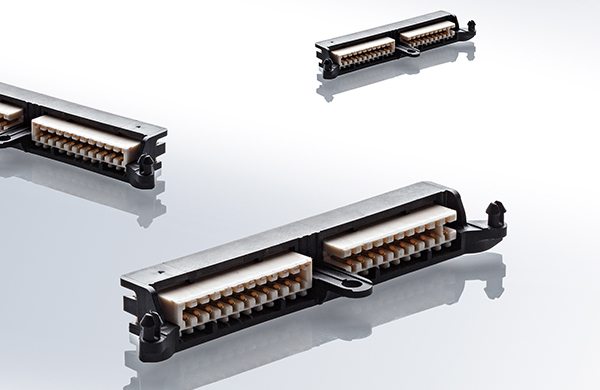

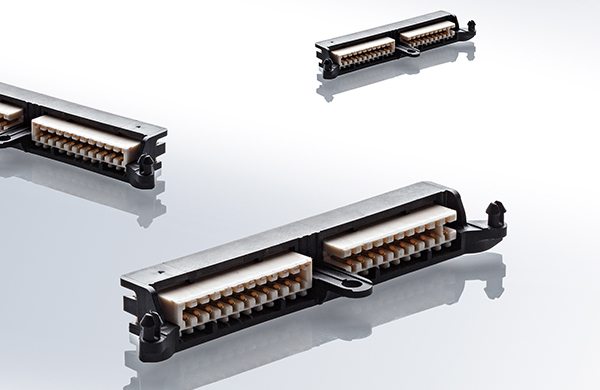

With a track record of expertise, our products and systems solutions support an industrial environment – worldwide. We engineer and produce connectors and contact systems, electromechanical elements and mechatronic components of outstanding quality for your individual technical application. We focus on automotive, building technology, home appliance and mobile radio networks – let Lumberg put its decades of connector design and manufacturing experience to work for you.

Research & Development at Lumberg

The right idea, a straight construction, completely equipped laboratories and precise system measurements are the primary steps in our developing projects. According to state-of-the-art methods and technologies we mobilize our established development expertise and our passion for feasibility for your product.

And we create consistently innovative and value adding solutions for your individual and complex requirements. In closest cooperation with specialists from your R&D we invent your custom-fit solution – early integration of our designing engineers into your project is the key to success.

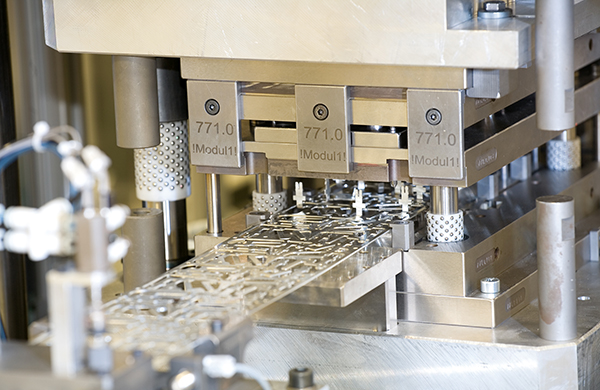

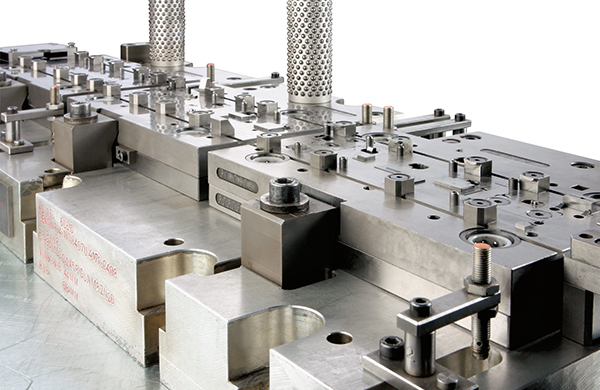

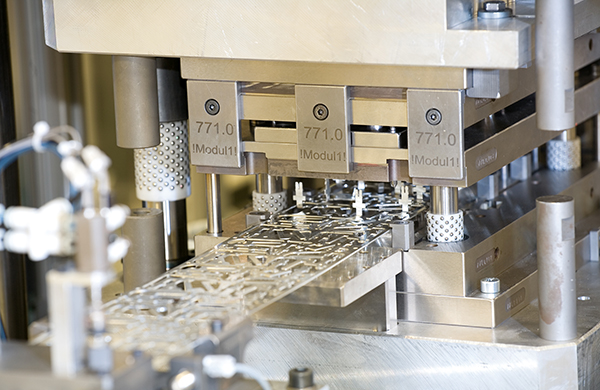

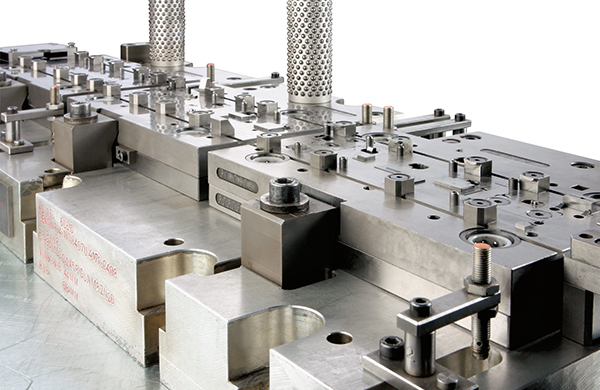

Machinery and Tools at Lumberg

A promise for quality we supply to your products: the construction and manufacturing of our tools in our own tool manufacturing as well as design and construction of assembly lines according to our standard – and to yours.

| In-house tool design and tool manufacturing for precision punching/bending dies and for injection molding tools |

| Development and manufacture of high-performance assembly lines for Lumberg connector systems (assembly speed up to 3.000 contacts per minute) |

| High degree of specialization in modular tooling technology to reduce plurality of tools |

| Design of camera inspection technology including in-house programming |

| Processing of quality materials for application in electromechanical components industries |

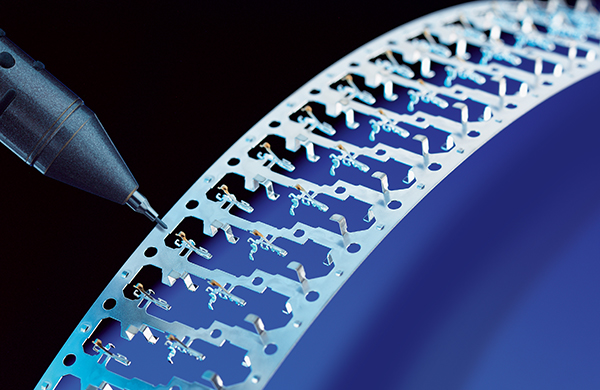

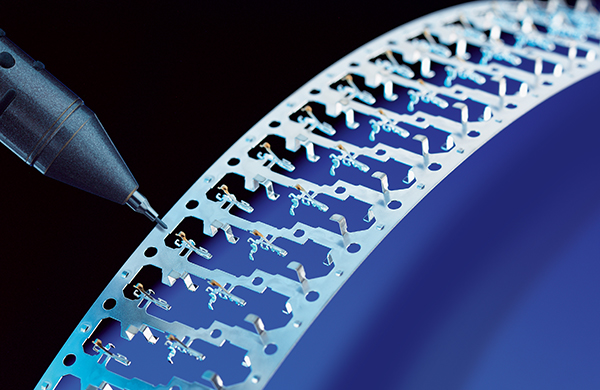

Production at Lumberg

Punching, injecting, assembling – means metals, plastics and highest degree of automation for the contact. With our production, including highest degree of company-internal value-add, e.g. with our own machinery and tool making, we are equipped for you.

| Punching and Bending Technology |

|---|

| Integrated punching units including precision leveler and ultrasonic degreasers |

| High-speed punching processes on Bruderer high-performance automatic machines |

| Integrated verification process at fixed points inside the compound tool-sets incl. data storage during punching at up to 1200 strokes/min. |

| Injection Molding Technology |

|---|

| Multi-cavity molds for up to 32-cavity tools incl. hot runner technology and runnerless injection molding for precision components |

| Integrated production units for highly-automated overmolding by adding several components such as metal contact elements |

| Assembly Technology |

|---|

| Development and manufacture of assembly lines for electromechanical sub-assemblies incl. integrated processing of active and passive components, electronic sub-assemblies, flashing software |

| In addition to mechanical and electrical inspections, strong integration of camera technology to check and store parameters that are critical to the components |

Skills at Lumberg

We continously develop for you: From standard connectors over micro contact systems, complex sub-assembly developments forward to a technical service provider for your customized applications.