Date Of Publication:2020-01-17 11:12 Click Rate:968

Definitions and terms

The physiological well-being of people is dependent on the level of humidity in the air, as are many technical processes. Air humidity is quoted either in terms of absolute humidity or relative humidity in measurements.

Saturated water vapour pressure ps

Like any moist gas, humid air is a mixture of dry gas and water vapour and reacts in accordance with Dalton’s law. A particular volume of a dry gas can only absorb a maximum mass of water vapour at a certain temperature. This value corresponds to the saturated water vapour pressure ps, which is dependent on the temperature.

The correlation between the saturated water vapour pressure ps and the temperature t is a natural characteristic curve which, in practice, can be described by the following approximation equation for temperatures above 0°C (over water):

The following equation applies for temperatures below 0°C (over ice):

In this state the gas is described as saturated.

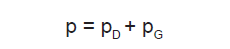

Water vapour partial pressure pD

If the mass of gas contained in the gas is lower, it is an unsaturated moist gas with a water vapour partial pressure pD. In that case, the total pressure of the gas is:

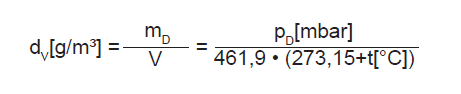

Absolute humidity dv

The mass of water actually contained per unit of volume of moist gas is described as absolute humidity dv, i.e. it corresponds to the specific volume and can be calculated using the equation of state for gases.

Degree of moisture or mixture ratio x

People refer to the dry state of a gas, rather than its moist state, in many sectors of industry. Consequently, the terms degree of moisture or mixture ratio x, signifying a state quantity, were introduced. It is defined as the mass of water contained in the unit of mass of the dry gas and, contrary to absolute humidity, is dependent on the pressure and type of the gas. The following equation applies for air:

Dew-point temperature ts

The dew-point temperature tS is another term used to describe the state of a moist gas. It is the temperature at which the moist gas becomes saturated, i.e. the temperature to which the gas would have to be cooled in order to prevent it absorbing any more water and at which condensation of its existing water content starts. The correlation between the saturated vapour pressure and the temperature is indicated by the water’s curve of vapour pressure. It follows from this that every dew-point temperature is assigned a specific water vapour pressure and, thus, a specific absolute humidity.

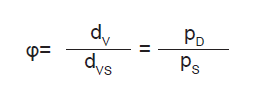

Relative humidity φ.

Relative humidity is a variable which is referred to very commonly in practice. It signifies the ratio between the absolute humidity actually contained in the gas at a certain temperature and the maximum saturation humidity possible:

Relative humidity is stated in percentage terms or as a number less than 1.

Measuring techniques

Just as a number of different measuring variables can be used to describe humidity, there are several techniques for measuring humidity levels with varying degrees of precision.

Hygrometric measuring techniques

Hygrometric measuring techniques are based on the change in the length of hygroscopic fibres, in particular hairs or synthetic fibres. While these hygrometers are a cost-effective solution, they can only be used within a limited measuring range. They offer a degree of precision of about ± 5% RH.

Psychrometer

Psychrometers are considerably more accurate than hygrometric measuring techniques. They measure moisture levels via the physical effect of the evaporative cooling process by taking two temperature readings. One of the thermometers records the ambient temperature, and a second one takes the so-called wet-bulb temperature. In order to do this, the thermometer is moistened by a cotton hose, and air is directed against it at a rate of 2 to 3 m/s. The evaporation which occurs cools down the thermometer and, in a state of equilibrium, the humidity can be calculated from the dry temperature and the wet-bulb temperature. A degree of accuracy of ± 1% RH is possible using accurate thermometers and by handling the equipment with the proper care.

Dew-point mirror

The dew-point mirror is another measuring technique which is very accurate. A metal-coated surface is cooled down to the temperature at which air starts to deposit dew. The temperature measured in this state corresponds to the dew-point temperature. Humidity can be calculated from this, with reference to the ambient temperature. Degrees of accuracy of ± 1% RH can also be achieved with this.

The latter two measuring techniques are fairly accurate, although they are expensive and complicated.

Capacitive humidity sensors

Capacitive humidity sensors have been used more commonly in recent times. They are inexpensive, require no maintenance and deliver very accurate measurement readings.

These sensors are based on capacitive humidity sensing elements. A small, thin glass or ceramic substrate provides a base for an electrode system, a humidity-sensitive polymer layer and a layer of gold which is permeable to water vapour.

Given the fact that the hygroscopic polymer layer can store molecules of water, which change in terms of their relative permittivity, this later system represents a humidity-dependent capacitor. The capacity of this capacitor is a measure of the ambient relative humidity.

The change in capacity is converted into an electrical output signal by electronics, which are generally positioned directly at the humidity sensing element. The two parts combine to create a capacitive humidity sensor, which is calibrated by humidity references. The degree of accuracy obtainable, which is essentially determined on the basis of linearity deviations, hysteresis, temperature-dependence and comparative measurements, is about ± 2% RH.

The capacitive humidity sensing elements manufactured by MELA Sensortechnik can be used within the complete humidity range, i.e. from 0% to 100%, are resistant to thawing and can be used within a temperature range of between –40°C and 200°C.

The humidity sensors made on this basis also span the complete measuring range of 0% to 100% RH and can be used within a temperature range of between –20°C and 80°C. Specially designed versions can be used at temperatures of up to 200°C.

The characteristic curve is almost linear; deviations in linearity are less than 2%. If the sensors are used for a long time in conditions of extremely low or high humidity, a draft of up to 2% RH occurs; this, however, disappears again once it has passed through the entire humidity range. A drift can also occur in different ways if it is exposed to a variety of polluting gases.

Thanks to their very high sensitivity, the capacitive humidity sensors are also ideal for measuring equilibrium humidity in hygroscopic materials. If the sorption isotherms of the hygroscopic materials are known, the level of humidity contained in the solid matter can also be ascertained.

Calibration

In order to maintain the high levels of measuring precision over a relatively long period of time, the characteristic curve can be checked regularly. MELA Sensortechnik provides humidity standards for checking and re-calibrating the sensors in-situ (product info sheet no. F 5.2).

Users requiring more precise calibration may avail of the company’s calibration service. A workshop test (test certificate with actual deviation from the workshop standard measured at 11%, 33%, 57%, 75% and 90% RH) can be performed, on request.