Choosing the Right Sensor Technology

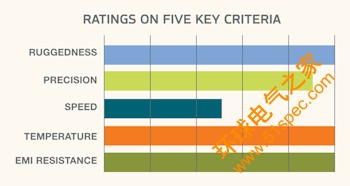

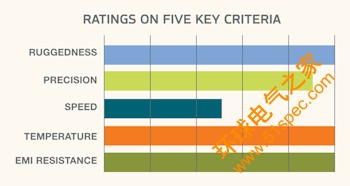

BEI Sensors offers a variety of speed and position sensing technologies. It's important to choose one that's suited to your particular application. The sensor's operating environment, required degree of precision, output type, speed, and physical configuration all must be considered. The descriptions of the different technologies on these pages will help guide you in choosing the optimal speed and position sensing technology.

Optical Technology

Optical sensing technology uses the interruption of light to detect movement. Optical encoders have an internal code disc with opaque lines or patterns that are rotated in the path of a light source, typically from an LED. The code disc acts like a shutter to alternately block (OFF) or unblock (ON) the light to an internal photodetector. The photodetector senses the alternating light beam, which the encoder's electronics convert into an electrical signal. This signal is passed to an external control system through the encoder's output.

Optical sensing technology is the most precise and offers the highest resolution of the position sensing technologies. It is also resistant to environmental magnetic interference and, when enclosed in a metal housing, highly resistant to EMI.

BEI Sensors' optical encoders are well sealed, allowing them to operate in harsh and dirty environments. They are also highly resistive to shock and vibration, and are capable of withstanding a 50 g, 11 msec shock pulse and 20 g's of vibration (5 to 2000 Hz).

This level of robustness makes BEI encoders well-suited for most industrial applications. BEI optical encoders are ideal for numerous types of industrial processes, such as oil well drilling, machine control, agricultural machinery, web process control, robotics, elevators, construction equipment, cranes, motor feedback and any closed loop control systems.

Magnetic / Hall Effect Technology

Magnetic sensing technology uses changes in magnetic fields to detect movement. There are two ways magnetic technology is integrated into the BEI Sensors offerings, digital encoders and analog Hall effect position sensors.

Magnetic encoders use a disc that has been magnetized with multiple, north/south pole pairs that are in the form of radial lines or patterns. In place of a photodetector, magnetic encoders use an ASIC designed to detect alternating north and south poles as the disc is rotated past it. As the ASIC senses the change in magnetic poles, internal electronics convert it into a digital electrical signal that is then passed through the device’s output.

In the Hall effect sensor configuration, the internal disc is magnetized with a single pole pair. The disc is attached to the sensor’s rotor which is then coupled to the motion being measured. The sensor’s ASIC is designed to detect the change in the direction of the magnetic field as the disc rotates above it. These changes in magnetic field are converted to an analog signal that is ratiometric (proportional) to the angle of the rotating disc.

Hall effect sensors are typically used to resolve angular position with an analog output while magnetic encoders are most often used to detect rotational speed and direction with a digital output.

Magnetic encoders tend to have lower resolution and precision than their optical counterparts and are more susceptible to environmental magnetic interference. However both products are ideal for operation in very high temperatures and environments with extreme shock.

Ideal applications for magnetic encoders include wind energy, tree harvesting, traction motors for rail equipment and pavement profiling. Hall effect sensors excel in steering, pedal and throttle for off-road equipment, dancer controls in web processing, flow control valves and elevator door opener applications.

Potentiometric technology

Potentiometric sensing technology is available in one of three configurations: wirewound, conductive plastic and hybrid.

Wirewound potentiometers are comprised of a resistive element (coil) and a contact spring (wiper).The coil is made from a very fine wire that is precisely wound onto a mandrel. The wiper, a specially engineered precious metal contact, wipes across the wound coil. The coil is fixed internally to the sensor's housing and the wiper is attached to the sensor's rotor which in turn is coupled to the motion being measured. A voltage is applied across the coil and the coil becomes a voltage divider. As the motion being measured rotates the wiper across the energized coil, a voltage proportional to the rotational position can be read between the coil and the wiper. The output changes in discrete steps as the wiper moves across the individual coil windings.

Conductive plastic potentiometers are very similar to wirewound, except that the wiper moves across a conductive plastic element rather than a coil. The conductive plastic element is comprised of a substrate and a resistive epoxy. In its pre-cured state this resistive epoxy material is referred to as "ink". The ink is applied to a cured, the ink acts very similarly to the coil in a wirewound potentiometer, with the advantage of having a very uniform, smooth surface. This surface provides a more continuous output and longer life as compared to a wirewound potentiometer.

As its name implies, hybrid potentiometers use a combination of the two previous mentioned configurations, using a wirewound coil coated with the conductive plastic material. Wirewound potentiometers provide the highest accuracy of the three configurations and dissipate power very well; however because of the metal-to-metal contact between the wiper and coil, wirewounds have a shorter operating life.

Conductive plastic potentiometers provide the highest resolution or output smoothness and have a higher operational life than wirewounds, however it is more difficult to get the high linearity (accuracy) available from a standard wirewound potentiometer.

Hybrid potentiometers are able to combine the best aspects of both other configurations. A hybrid potentiometer has a better ability to dissipate power (over conductive plastic pots) and has improved resolution or output smoothness (similar to conductive plastic potentiometers).

The use of conductive plastic material gives hybrids a longer operating life over wirewounds.

Potentiometers in general have several benefits including small package size and weight, resistant to electromagnetic interference (EMI), temperature stability and are able to work at very high (300C max) and low (-55°C) operating temperatures.

Ideal applications include aircraft control surfaces, in-cylinder hydraulics and oil field downhole measuring.