One of the key differences between conventional internal combustion engine vehicles and hybrid electric vehicles (HEVs) or electric vehicles (EVs) is the presence of multiple batteries and voltage levels. Internal combustion engines operate from a single 12-V or 24-V battery, which is typically a lead acid battery. But HEVs and EVs use a secondary high-voltage battery that ranges from 48 V for HEVs to much higher voltages – 400 V to 800 V for EVs.

The presence of multiple voltage levels requires isolation to protect the low-voltage circuitry from high voltages. While it seems obvious that you’d need isolation for 400-V batteries and beyond, do you need isolation in 48-V mild hybrid systems? Let’s find out.

Isolation in 48-V HEVs

Even if the voltages are not as high as 400 V or 800 V, there are several reasons why isolation is important for 48-V hybrid vehicles, including increased noise immunity and fault protection.

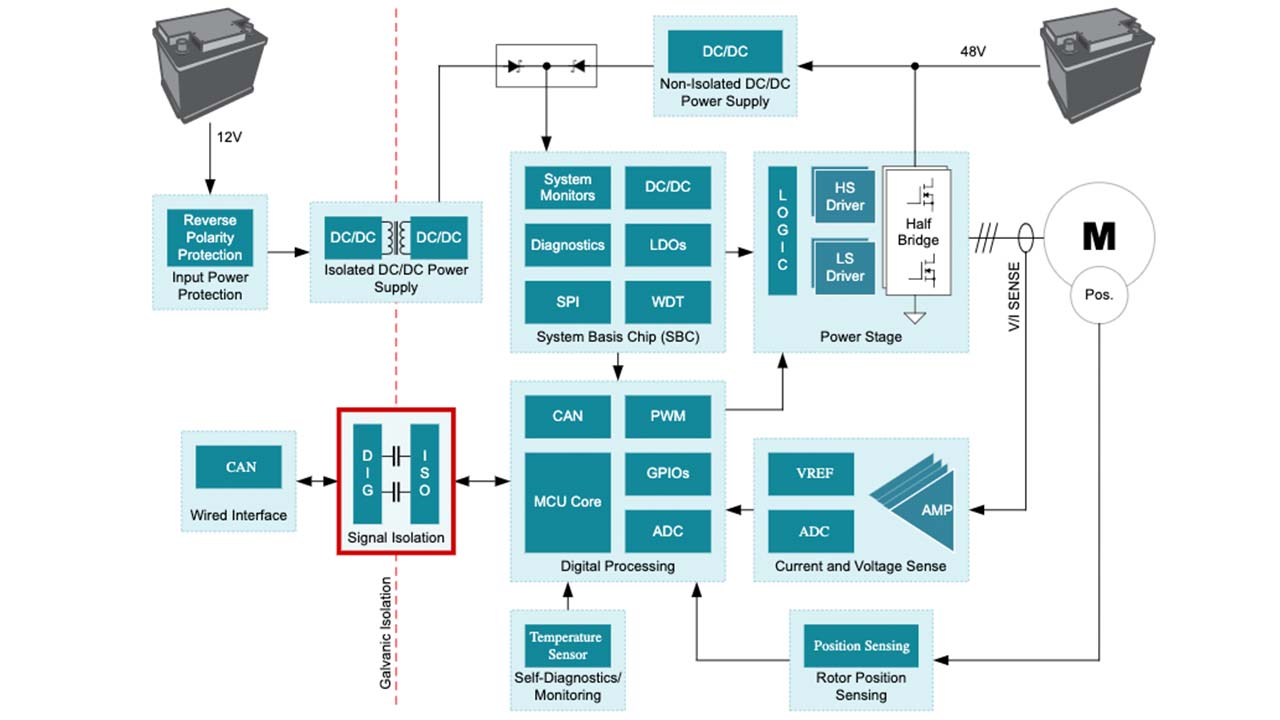

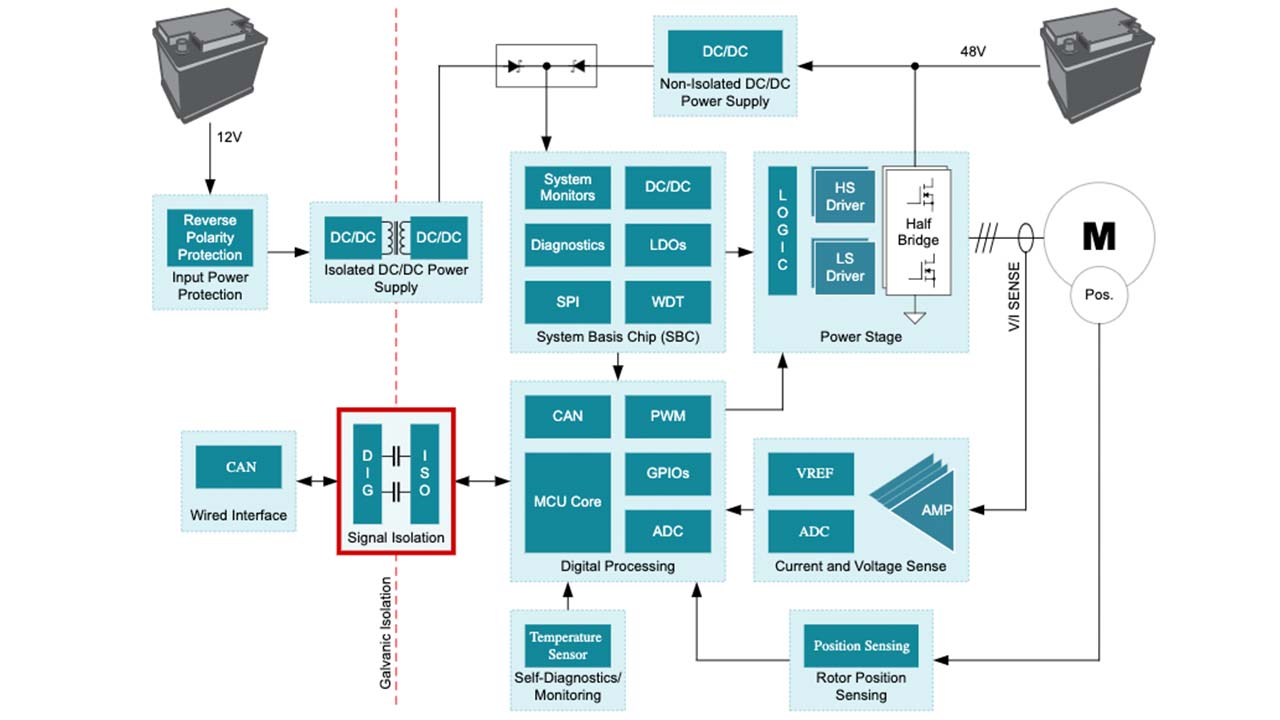

Figure 1 shows a starter generator system where the power stage, which includes the H-bridge and the field-effect transistors (FETs), is on the 48-V side. The switching of these FETs causes voltage transients (dv/dt) that may induce some common-mode noise on the 48-V ground. In the absence of any isolation, this noise will couple with the 12-V side and affect the signal integrity of circuits on the low-voltage side. By adding isolation between the two sides, as shown in Figure 1, you can improve common-mode transient immunity and signal integrity.

Figure 1: Starter/generator subsystem in a 48-V HEV

Temperatures up to 150°C in your HEV/EV system? No sweat!

|

The industry's first AEC-Q100 Grade 0 digital isolator, the ISO7741E-Q1, helps you save design time, cost and space in automotive designs where ambient operating temperatures can exceed 125°C.

|

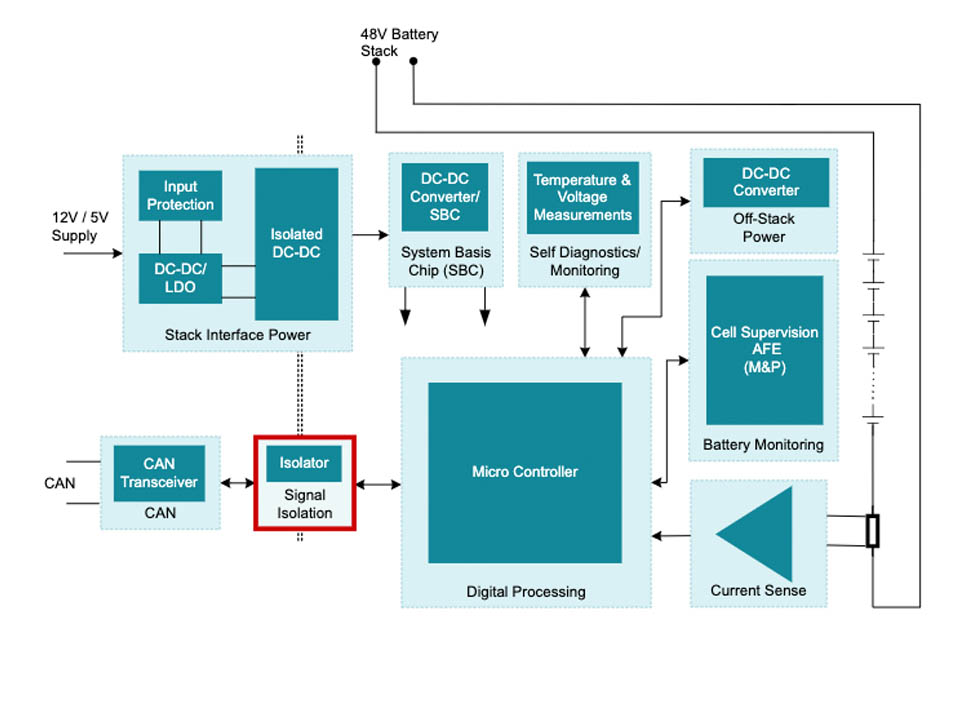

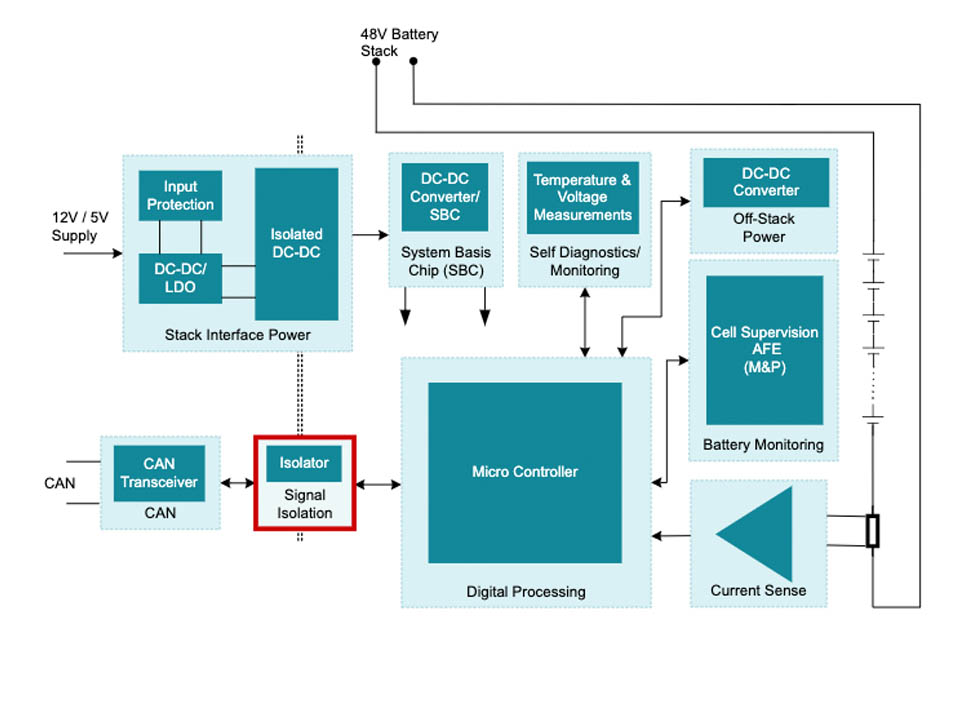

In Figure 2, a 48-V battery stack and microcontroller (MCU) in a battery management system (BMS) sits on the high-voltage side, while the MCU communicates with the electronic control unit using the Controller Area Network (CAN) protocol. If there is a fault on the 48-V side, the voltage could appear on the 12-V side. The circuit components on the low-voltage side (a CAN transceiver in this case) may not be able to withstand the high voltage and could become damaged. Having an isolator between the CAN transceiver on the low-voltage side and the microcontroller on the high-voltage side will ensure the safety of the low-voltage circuitry even if there is a fault on the high-voltage side.

The Verband der Automobilindustrie 320 (VDA320) standard for electric and electronic components in motor vehicles specifies a fault current test (E48-20) where the test voltage is applied across the 48-V/12-V barrier and the expected current between the 12-V and 48-V system must be less than 1 μA. The presence of an isolator ensures that the current will meet the standard.

Figure 2: 48-V BMS block diagram

If you are designing 48-V HEV systems and looking for isolation devices to interface with the 48-V side, there are a few options for communication between the 48-V side and 12-V side, depending on the interface standards.

For designs that require Serial Peripheral Interface (SPI), Universal Asynchronous Receiver Transmitter (UART) or general-purpose input/output (GPIO) communication between the 12-V and 48-V sides, you can use digital isolators such as the ISO7741-Q1 or ISO7721-Q1, depending on the number of channels of isolation you need.

When you are using I2C communication to save the number of signal traces, isolated I2C devices such as the ISO1540-Q1 (bidirectional data, bidirectional clock) or ISO1541-Q1 (bidirectional data, unidirectional clock) would serve the purpose.

If CAN communication exists between the two sides and isolation becomes necessary, you could add a digital isolator like the ISO7721-Q1 in series with the CAN transceiver or use an integrated isolated CAN device such as the ISO1042-Q1 to save some space.

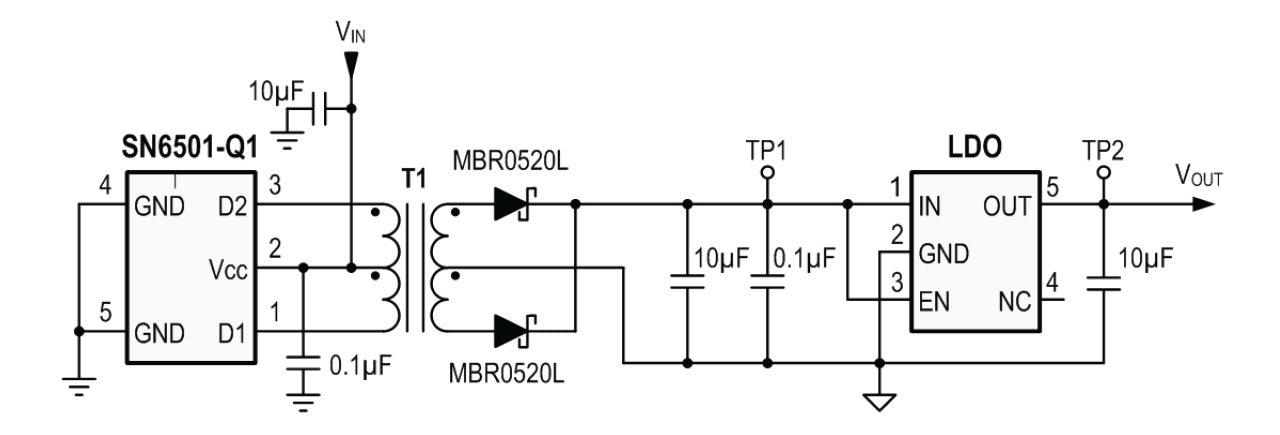

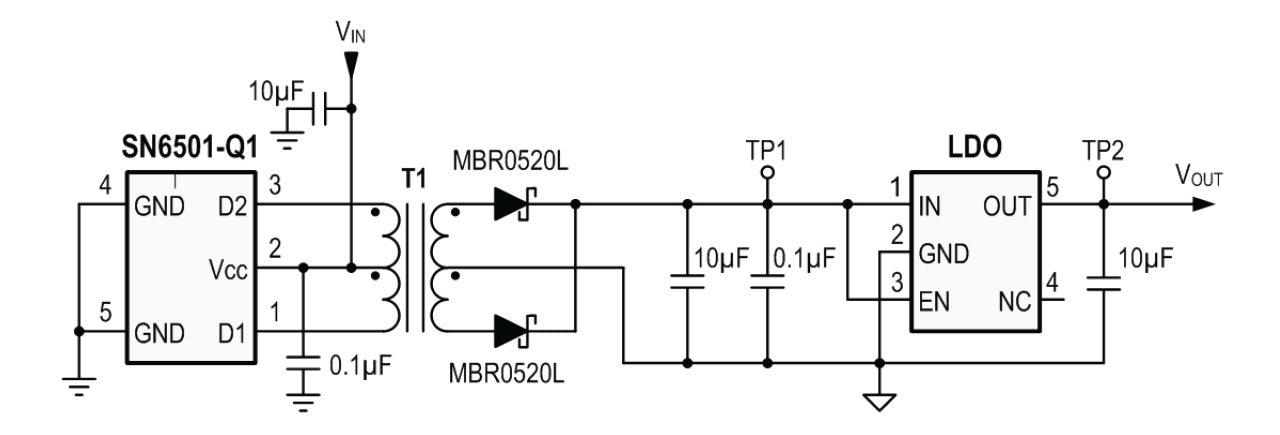

Data communication is just one part of the solution. You also have to isolate the power supply between the two sides, which you can achieve using flyback, fly-buck or push-pull topologies. For localized power supplies (for example, power for an isolated CAN transceiver), consider a transformer driver such as the SN6501-Q1, SN6505A-Q1 or SN6505B-Q1, that can be used with an external transformer, rectifier and low-dropout regulator, to generate a simple isolated power supply, as shown in Figure 3.

Figure 3: Simple circuit for an isolated power supply with a regulated output

The key differences between the SN6501-Q1, SN6505A-Q1 or SN6505B-Q1, is the output current of each driver, presence of spread spectrum to reduce emissions and different switching frequencies. These options enable you to select the right device to meet the emissions standards and power-supply requirements for your system.

While I’ve discussed these solutions within the context of 48-V HEVs, the isolation specifications of these device families and wider package options make these families suitable for EVs with higher battery voltages as well. It is possible to reuse the isolated sections from HEV subsystems in EV designs with minor modifications, which can save you both design and layout time.

Additional resources