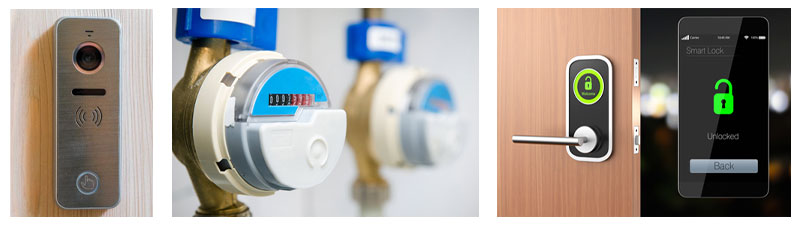

There are many approaches to designing low-voltage systems in motor-driven building automation and grid infrastructure applications such as smart meters, smart locks, Internet Protocol (IP) network cameras and video doorbells, as shown in Figure 1.

Figure 1: Battery-powered systems: a video doorbell, smart utility meter and electronic smart lock

Common challenges when designing motor-drive systems for these applications include demand for long-lasting, resilient and safe motor operation; ever-shrinking printed circuit board (PCB) space; and meeting the needs of numerous system requirements. These challenges require special care when considering motor-driver current consumption; integrated circuit (IC) and necessary component board size; and design simplification, flexibility and scalability to meet the needs of multiple platform types.

Reducing power consumption

In battery-powered motor-driven systems like smart locks, video doorbells, and gas and water meters, reducing overall power consumption by maintaining a low current draw when not actively driving a motor is an essential part of the design process to keep consumers from having to change batteries often. TI has reference designs for electronic smart locks and IP network camera infrared cut filters, if you’re interested in implementations of these applications.

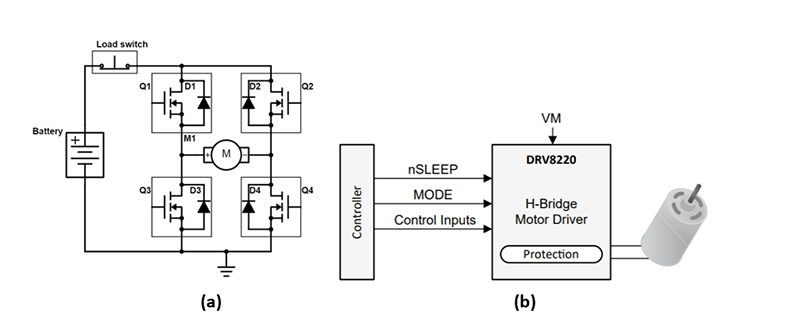

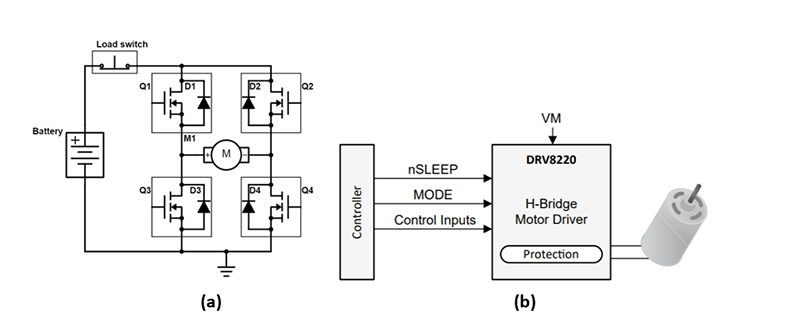

Let’s compare two ways to reduce power consumed by the H-bridge when the motor isn’t being driven, using:

- A discrete load switch between the battery and the motor-driver circuit to connect or remove power.

- A device such as TI’s DRV8210, which features a dedicated low-power sleep mode that draws a typical sleep current of 37 nA.

Compared to the first option, the second option reduces PCB space by as much as 50% and removes a power-dissipative element while the H-bridge power is connected. See Figure 2.

Figure 2: A simplified implementation of an H-bridge with low-power sleep function using an external cut-off switch (a); TI’s DRV8210 with automatic sleep mode (b)

Reducing PCB and motor-drive subsystem size

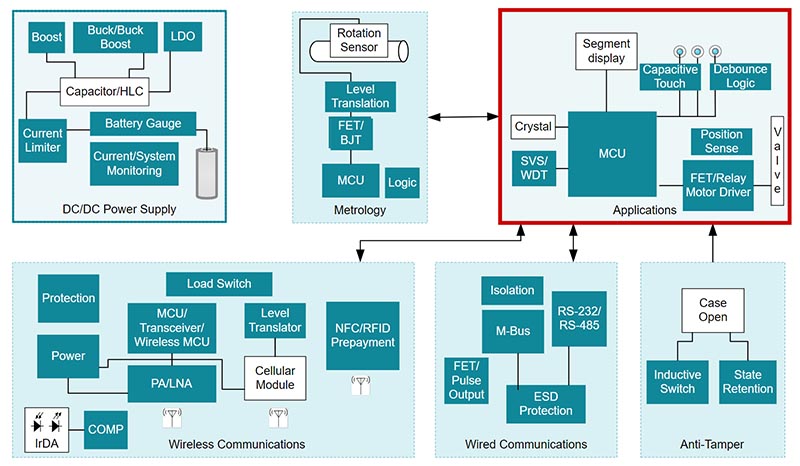

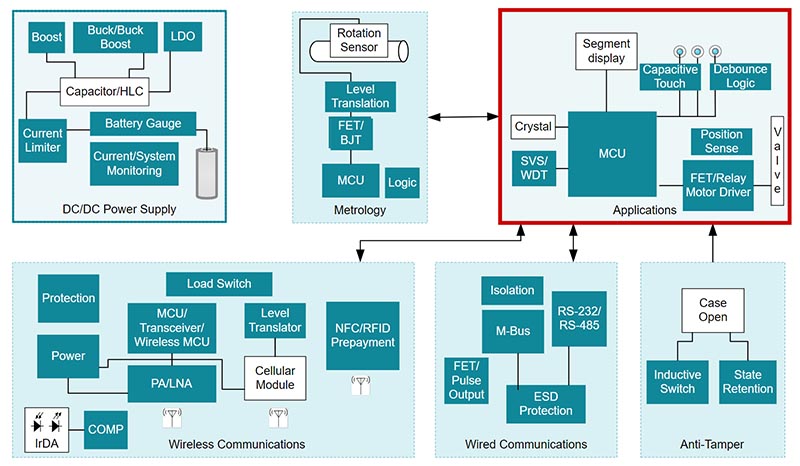

Modern smart meters and other low-voltage motor-driven applications are becoming increasingly more advanced, integrating sensing, wireless and wired communications, power management, and many other blocks, as shown in Figure 3.

Figure 3: Reference design for a rotary water meter

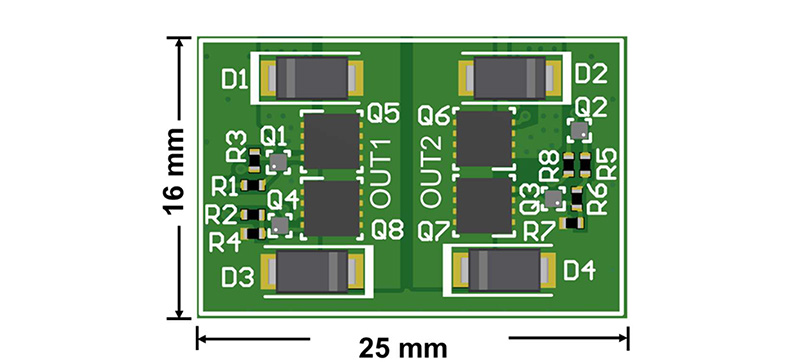

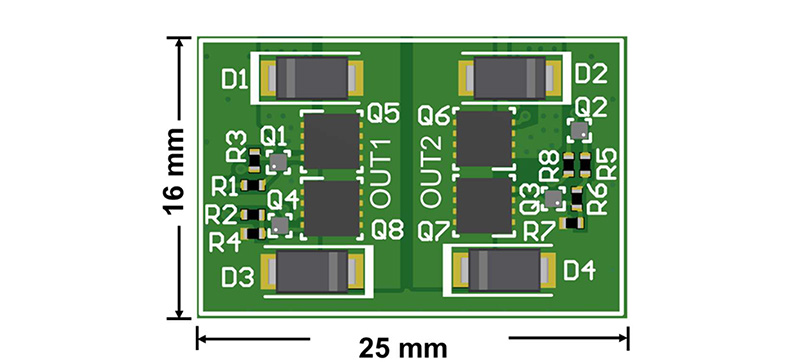

The sheer number of these blocks means that you must ensure that subsystems such as the motor driver and surrounding components use as little PCB space as possible. Figure 4 shows a commonly used discrete H-bridge implementation for driving a low-voltage brushed-DC motor. It is lacking some necessary functions, however, such as protection for overcurrent, undervoltage lockout, and thermal shutdown and dead-time control, which would take additional firmware and hardware effort.

Figure 4: Discrete implementation of an H-bridge and the basic surrounding circuit; the PCB area is 16 mm by 25 mm, or 400 mm2

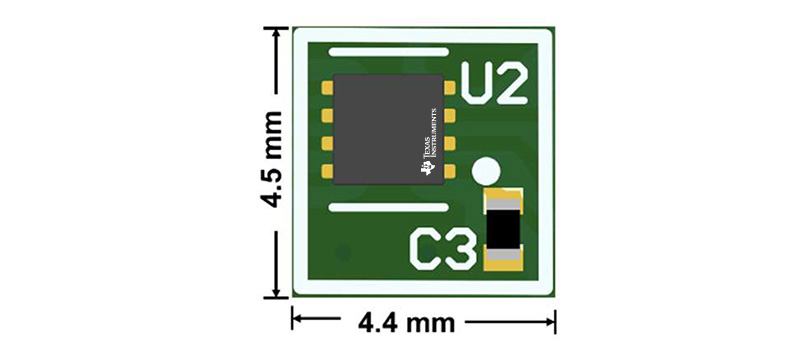

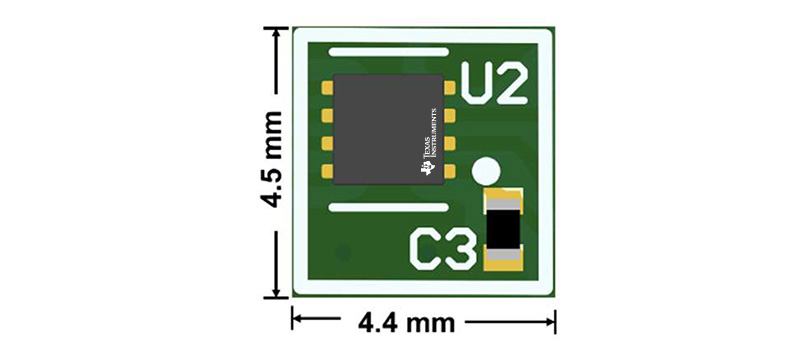

Compared to the discrete implementation, a motor-driver IC such as the DRV8220, with 4-mm2 and 1.92-mm2 package options, can reduce PCB space by 93% or more, as shown in Figure 5. Check out the technical article, “Not So Risky Business: Discrete vs. Integrated” to learn more about how our motor drivers reduce board space and component count. In addition, all TI brushed-DC motor drivers, including the DRV8220, provide integrated dead-time control and protection against overtemperature, undervoltage lockout and overcurrent events, which reduces the need for additional components, further reducing PCB space.

Figure 5: The DRV8220DSG integrated motor-driver layout; the PCB area is 4.5 mm by 4.4 mm, or 19.8 mm2

Design flexibility, simplification, reuse and scalability

Many applications in building automation, grid infrastructure and personal electronics have multiple platforms with differing system requirements. Take, for example, a smart sanitation company that designs soap dispensers, automatic toilets, paper towel dispensers and similar applications, as shown in Figure 6. These applications require different types of loads for automation: a bidirectional brushed-DC motor for the dispenser valve, a latching solenoid for the flushometer valve and a single-direction brushed-DC motor for paper towel dispensing.

Figure 6: Common motor-driven smart sanitation applications

Ideally, you could use a flexible solution for all of these scenarios, but that normally requires significant time and effort to find discrete components or ICs that have a pin-to-pin solution across voltage and current ranges. Achieving this simplification, scalability and interface flexibility provides the ability to drive different motors, relays, solenoids and other types of loads with the same or similar driver. It also allows for design reuse, which greatly reduces time to market. See Section 9 of the DRV8210 data sheet for more details on how the DRV8210 motor-driver family helps achieve these benefits.

As demonstrated in this article, the numerous low-voltage and battery-powered platforms in building automation and grid infrastructure applications require motor drivers to be flexible, scalable and simple to design with. At the same time, these motor-drive systems must offer an aggressive low-power sleep mode for maximizing battery run time and take up only a small portion of PCB area to allow adequate room for many other system components. Check out our low-voltage H-bridge motor drivers for more information on how TI achieves these benefits of small size, low power consumption and design scalability.